Mechanical Training

Non Destructive Testing

Non-Destructive Testing (NDT) Training from the CORE Training Centre – comprehensive NDT training, examinations and certification for your personnel in accordance with International, American and European Standards

Anyone conducting NDT requires accredited training and certification. The innovative CORE NDT Training Centre in India provides state-of-the art training, examinations and certification in accordance with European, international and American standards such as EN ISO 9712 and ASNT.

Dive into Non-destructive testing with our hands-on, experience-driven training program. Enjoy direct instructor coaching and active industry knowledge from India’s highest level training facility.

Non Destructive Testing (NDT) is a specialized branch of engineering science which use of non-invasive techniques to determine the integrity of a material, component or structure without impairing its usefulness and is an integral part of Quality Assurance and Quality Control. It confirms quality of materials such as structural beams, pipes, plates, valves, nozzles etc. used in construction of industrial equipment’s. It also confirms quality of fabrication and joining process where testing of welds is of major importance. General procedure for NDT has given in ASME Section V and engineers have to follow these procedures for each NDT methods. Hence NDT training and certification is a must for QA/QC Engineers. We conduct NDT certification as per the requirements of ASNT - SNT TC 1A 2020 and other standards.

Any course can be offered at any CORE’s office or on site at the customer’s location.

Who Should Attend?

This course will benefit NDT personnel, maintenance personnel, Quality Assurance / Quality Control Inspectors, engineers, surveyors, technicians, trainees in the aerospace, metal fabrication, oil refinery, petrochemical, offshore, shipbuilding, ship-repairing and building construction industries.

Advance NDT Courses

Specialized NDT Courses

Basic NDT Level I & II courses

Advance NDT Courses

What is Eddy Current Testing?

Eddy current testing uses the electromagnetism principle for flaw detection in conductive materials. A specially designed coil energised with an alternating-current is placed in proximity to the test surface, generating a changing magnetic field that interacts with the test-part and produces eddy currents in the vicinity. Variations in the changing phases and magnitude of these eddy currents are then monitored through the use of a receiver-coil or by measuring changes to the alternate current flowing in the primary excitation-coil. The electrical conductivity variations, the magnetic permeability of the test-part, or the presence of any discontinuities, will cause a change in the eddy current and a corresponding change in phases and amplitude of the measured current. The changes are shown on a screen and are interpreted to identify defects. This Eddy current inspection method is suitable for the larger surfaces than smaller surfaces as it damages the surface areas like cracks, subsurface cracks, pits, corrosions, inner surfaces, and other minor damaged areas. It sustains with large durability for complex surfaces shapes and different sizes. The Eddy Current tool is widely used in various important sectors such as:- Aircraft

- Military

- Petrochemical

- Aerospace and

- Other commercial Industries

- Electromagnetic theory

- Test instrumentation and coil design

- Basic impedance plane principles

- Conductivity

- Dimensional factors (lift-off and material thickness)

- Permeability

- Frequency, signal-to-noise ratio, and flaw detection applications

- Weld inspection on ferrous and non-ferrous materials

Training Course Objectives

- Describe the basic principles of the eddy current test method

- List several applications of the eddy current test method

- List the types of discontinuities detected with the eddy current test method

- Describe the cause and effect of various types of discontinuities

- Describe the operational steps in the eddy current test and understand the importance of each step following a written procedure

- Interpret and evaluate the test results with respect to the applicable standards

- Complete the required test reports, and prepare a clear and concise written instruction (Procedure)

- Locate defects in various materials, components and structures with a high probability of detection

About Qualification

Level 1: General Qualification required for separate certification

10th Grade, SSLC, +2, HSC, Diploma – above or equivalent.Level 2 Direct: General Qualification required for separate certification

Level 1 With 6 month’s industrial experience or Science Graduation, Engineering Graduation.Course Duration

Will vary depends on the type of certification chosenPhased Array Ultrasonic Testing (PAUT) Level 2

Phased Array is an advanced pulse-echo technique that utilizes multiple miniaturized transducers and time-delays to shape the ultrasonic sound beam to a desired angle and focus. The versatility of the system permits simultaneous views of different presentations, such as sectorial views as well as A Scan, B-Scan C-Scan representations In comparison with manual pulse-echo techniques, the advantages of Phased Array testing are its excellent repeatability, increased inspection speed, more accurate results and the ability to inspect complex geometries and to visualize indications in welds and/or base materials using B, C, D and S scans (with all A-scans included). Moreover, Phased Array allows the digital storage of all data, location and system settings, and is very much safer to operate within a working environment, compared with Non-Destructive Testing methods that use X-rays and gamma-rays for detecting imperfection. This course follows the ASNT – Level II Phased Array syllabus and is designed to take the experienced NDT technician though the fundamentals of Phased Arrays, including Principles, Digitization and History of Phases Arrays, supported by a series of lab applications that will have the end user proficient with the Phased Array process, encoding scans, compiling groups and basic interpretation. We can provide Phased Array Training courses and examinations suitable for the following certification scheme.- SNT-TC-1A in accordance with your/our company written practice An example of the syllabus that is used for Phased Array training courses is shown below for Level 2. CORE can tailor make the syllabus to satisfy the requirements of an individual’s company specific written practice if requested.

- COURSE CURRICULUM

- Principles of Inspection Sensitivity

- Phased Array Instrument

- Scanning with Phased Array Probes

- Calibration and Checks

- Software and Data collection Analysis

- Data Acquistion and Interpretation

- The technician should leave the course with a sound understanding of Phased Arrays

- The technician will be able to carry out basic operations functions, including calibration, detection and Identification of indications

- The technician, with dedicated application will be able to apply code compliant examinations to welded components

Specialized NDT Courses

NDT Engineering

NDT Engineering program is a course package for candidates whom seek a career in NDT Inspection/Quality Department. Qualification required: B-Tech, B.E, – above or equivalent Course Duration: 45 Days Course Syllabus: Course Contains the same topics mentioned above in each methods level 1 & level 2 course details & according to the SNT-TC-1A/CP-189, CP-105 Latest Editions following at the Institution. After successful completion of this course the candidates will be enough classroom trained to work as an NDT Engineer in the Industry, detailed understanding of each modules and hands on practical experience are available for each candidate to enrich their knowledge on the respective subject along with lot of supportive and infotainment activities for the ease in understanding their roles and responsibilities. Course Content:- Radiography Testing

- Ultrasonic Testing

- Liquid Penetrant Testing

- Magnetic Particle Testing

- Radiography Testing Film Interpretation

- Ultrasonic Testing Plate & Pipe Butt Weld Scanning

- Ultrasonic Testing Plate Scanning

- Visual Testing

- Introduction to Welding Engineering

- Material and Processes

- Defects(Causes and Remedies)

- Topical Briefing on Advanced NDT Techniques

- Soft skills and Job skill Development

NDT Inspection

NDT Inspection who seeks career in NDE/NDT, Third Party Inspections, Quality Department. After successful completion, each candidate will be enough trained equivalent to an engineer of 2 years relevant experience in handling various duties and responsibilities of NDT Inspector in the respective industry, detailed understanding of each modules and hands on practical experience are available for each candidate to enrich their knowledge on the respective subject along with lot of supportive and infotainment activities for the ease in understanding their roles and responsibilities. After Successful Completion of this course,- Radiography Testing

- Ultrasonic Testing

- Liquid Penetrant Testing

- Magnetic Particle Testing

- Radiography Testing Film Interpretation

- Visual Testing

- Implementation for NDE method and techniques

- Metals and Metallurgy

- Material and Processes

- Defects (Causes and Remedies)

- Topical Briefing on All NDE Methods

NDT Technician

NDT Technician program is a course package for candidates whom seek a career in NDT; this course contains following NDT methods:- Radiography Testing

- Ultrasonic Testing

- Liquid Penetrant Testing

- Magnetic Particle Testing

- Radiography Testing Film Interpretation

Basic NDT Level I & II courses

Visual Inspection

- 8 hours (SNT-TA-1A)

- 70 hours in method & 130 hours in NDT

- 16 hours Training (SNT-TC-1A) (additional to the hours for Level 1)

- 140 hours in method & 270 hours in NDT (SNT-TC-1A)

- Preparation training for ASNT Level 3

| General Theory | Specific Theory | Practical Examination |

|---|---|---|

|

Application of the Method and use of Codes, Specifications and Procedures, applicable to the company, including the relevant control checks. | Follow written instructions and process the inspection test pieces, record and report defects from know datum markers, carry out pre test calibration checks, post test procedures. |

| General Theory | Specific Theory | Practical Examination |

|---|---|---|

(in addition to the Level 1 Syllabus above)

|

Application of the method to the specific requirements of the company, in particular making reference to those Codes, Specifications and Procedures used by the company, including the relevant control checks. Product technology of the products for the relevant sector, i.e. welds, castings, forgings, this includes, manufacturing processes, defect formation and detection. | Production of written instruction, determine the best inspection techniques for the individual parts, process the inspection test pieces, record and report defects from know Datum markers, carry out pre test calibration checks, post test procedures. |

About Qualification

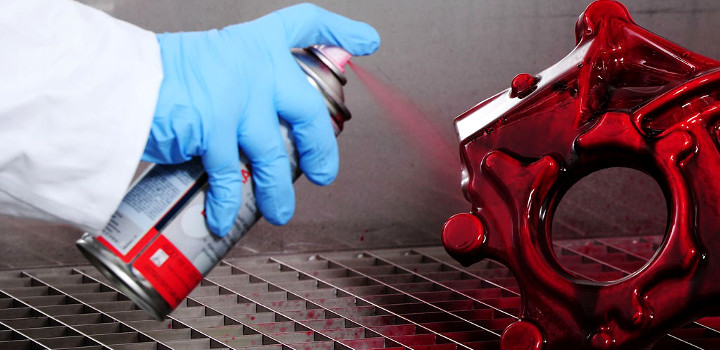

Level 1 General Qualification required for separate certification: 10th Grade, SSLC, +2, HSC, Diploma – above or equivalent. Level 2 Direct – General Qualification required for separate certification: Level 1 with 6 month’s industrial experience or Science Graduation, Engineering Graduation. Course Duration Will vary depends on the type of certification chosenPenetrant Testing

- SNT-TC-1A in accordance with your/our company written practice

- Preparation training for ASNT Level 3

| General Theory | Specific Theory | Practical Examination |

|---|---|---|

|

Application of the Method and use of Codes, Specifications and Procedures, applicable to the company, including the relevant control checks. | Follow written instructions and process theinspection test pieces, record and report defects from know datum markers, carry out pre test calibration checks, post test procedures. |

| General Theory | Specific Theory | Practical Examination |

|---|---|---|

(in addition to the Level 1 Syllabus above)

|

Application of the Method to the Specific requirements of the company, in particular making reference to those Codes, Specifications and Procedures Used by the company, including the relevant control checks. Product technology of the products for the relevant sector, i.e. welds, castings, forgings, this includes, manufacturing processes, defect formation and detection. | Production of written instruction, determine the best inspection techniques for the individual parts, process the inspection test pieces, record and report defects, carry out pre test calibration checks, post test procedures. |

About Qualification

Level 1 General Qualification required for separate certification: 10th Grade, SSLC, +2, HSC, Diploma – above or equivalent. Level 2 Direct – General Qualification required for separate certification: Level 1 With 6 month’s industrial experience or Science Graduation, Engineering Graduation. Course Duration: Will vary depends on the type of certification chosenMagnetic Particle Testing

- Preparation training for ASNT Level 3

| General Theory | Specific Theory | Practical Examination |

|---|---|---|

|

Application of the Method and use of Codes, Specifications and Procedures, applicable to the company, including the relevant control checks. | Follow written instructions and process the inspection test pieces, record and report defects from know datum markers, carry out pre test calibration checks, post test procedures. |

| General Theory | Specific Theory | Practical Examination |

|---|---|---|

(in addition to the Level 1 Syllabus above)

|

Application of the method to the specific requirements of the company, in particular making reference to those Codes, Specifications and Procedures used by the company, including the relevant control checks. Product technology of the products for the relevant sector, i.e. welds, castings, forgings, this includes, manufacturing processes, defect formation and detection. | Production of written instruction, determine the best inspection techniques for the individual parts, process the inspection test pieces, record and report defects from know Datum markers, carry out pre test calibration checks, post test procedures. |

About Qualification

Level 1 General Qualification required for separate certification: 10th Grade, SSLC, +2, HSC, Diploma – above or equivalent. Level 2 Direct – General Qualification required for separate certification: Level 1 With 6 month’s industrial experience or Science Graduation, Engineering Graduation. Course Duration: Will vary depends on the type of certification chosenUltrasonic Testing

- 40 hours Training (SNT-TC-1A)

- 210 hours work experience in method and 400 hours work experience in NDT(SNT-TC-1A)

- SNT-TC-1A in accordance with your/our company written practice

- We can also provide preparation training for ASNT Level 3

| General Theory | Specific Theory | Practical Examination |

|---|---|---|

|

|

Follow written instructions and process the inspection test pieces, record and report defects from know datum markers, carry out pre test calibration checks, post test procedures. |

| General Theory | Specific Theory | Practical Examination |

|---|---|---|

(in addition to the Level 1 Syllabus above)

|

|

Production of written instruction, determine the best inspection techniques for the individual parts, process the inspection test pieces, record and report defects from know Datum markers, carry out pre test calibration checks, post test procedures. |

About Qualification

Level 1 General Qualification required for separate certification: 10th Grade, SSLC, +2, HSC, Diploma – above or equivalent. Level 2 Direct – General Qualification required for separate certification: Level 1 With 6 month’s industrial experience or Science Graduation, Engineering Graduation. Course Duration: Will vary depends on the type of certification chosenRadiography Testing

- Radiographic Testing

- Radiographic Film Interpretation

- Basic Radiation Safety (BRS)

- Practical Examination of the Specimens

- 40 hours Training SNT-TC-1A

- 210 hours experience in method & 400 hours in NDT Level 2

- 40 hours (SNT-TC-1A) Training (additional to the 40 hours for Level 1)

- 630 hours work experience in method & 1200 hours experience in NDT (SNT-TC-1A)

- SNT-TC-1A in accordance with your/our company written practice

- Preparation training for ASNT Level 3

| General Theory | Specific Theory | Practical Examination |

|---|---|---|

|

Application of the Method and use of Codes, Specifications and Procedures, applicable to the company, including the relevant control checks | Follow written instructions and process the inspection test pieces, record and report defects from location markers, carry out pre test calibration checks, post test procedures. |

| General Theory | Specific Theory | Practical Examination |

|---|---|---|

(in addition to the Level 1 Syllabus above)

|

Application of the Method to the Specific requirements of the company, in particular making reference to those Codes, Specifications and Procedures Used by the company, including the relevant control checks. Product technology of the products for the relevant sector, i.e. welds, castings, forgings, this includes, manufacturing processes, defect formation and detection. | Production of written instruction, determine the best inspection techniques for the individual parts, process the inspection test pieces, record and report defects from know location markers, carry out pre test calibration checks, post test procedures. |